Definitions

Trace

A trace is a current carrying path on a circuit board.

Pads

Pads are the points of contact on the printed circuit board. Pads are circular/elliptical or rectangular shapes of copper on the PCB where the integrated circuits (ICs) get attached using solder.Via

A via is a hole that connects two layers of a PCB. It can be thought of as a jumper that connects a trace on one layers of a PCB to a trace on a second layer.

|

| Pads, Vias and Traces on a PCB |

Base material

Base material is PCB board onto which the circuit is printed. there are many kinds of base materials available for making PCBs the most common of which is FR-4. (more details on the material properties will be discussed in the post on FR-4 material).

|

| FR 4 base material |

Solder mask

The characteristic green color of a printed circuit board is because of what is known as a solder mask. The purpose of solder mask is to protect the traces from getting oxidized. Solder mask keeps the pads and other contact points clear while the places where no soldering is required, are sealed.Silk Screen

The writing on the printed circuit board is known as silk screen. Silk screen is used to mark the components and pads etc. on the circuit board for easy recognition.

|

| Green Colored Solder Mask and Silk Screen (White writing) |

Single Layer PCB

A single layer PCB has circuit traces and pads on only one side of the base material. the ICs are mounted from the opposite side.

Double Layer PCB

A double layered PCB has traces and pads on both sides of the circuit. The two sides of the double layered circuit board are connected by special type of connections known as "via".

Multi-Layered PCB

A multi layered PCB as the name implies, consists of many layers of traces. each layers is connected to others through vias. A typical example of a multi-layered PCB is the motherboard of a computer.

Fiducial Mark

A fiducial mark is a reference mark on a PCB whose purpose is to guide the PCB plotter to adjust its alignment. Advanced PCB plotting machines have a fiducial recognition camera that can detect the fiducial and automatically align the plotter head. The fiducial marks are not connected to any trace.

|

| Fiducial marks on a PCB with blue solder mask |

Copper Clad

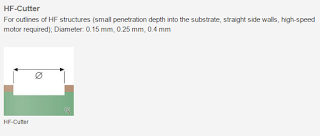

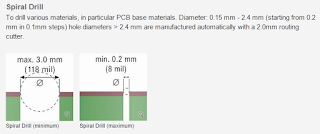

A copper clad board is the base material of a PCB. The base material as explained above is made from FR-4 (Fire-Retardant 4) which is basically a mixture of fiber glass and epoxy resin. This substrate is lined with a film of copper on one side to be utilized as a PCB base material.Routing

Routing is the arrangement of traces and pads on a printed circuit board.I will add more definitions with time. For any further information please contact saarizvi4@hotmail.com